For reasons similar to those that explain why other watch brands are incorporating carbon composites into their movements, Ulysse nardin watches dubai Replica has been placing its bets on the benefits of silicon in watchmaking ever since 2001, when it presented the Freak, the first watch fitted with a silicon escapement. Ten years ago, the brand’s first Innovision watch presented ten new innovations, all but one of which were based on silicon technology and have since been incorporated into the Ulysse Nardin collection. The Innovision 2, unveiled at SIHH 2017, showcases the state of the art in silicon technology and offers a hint of where the industry could be headed over the next decade.

Here are the 10 innovations that could shape the future of mechanical watchmaking:

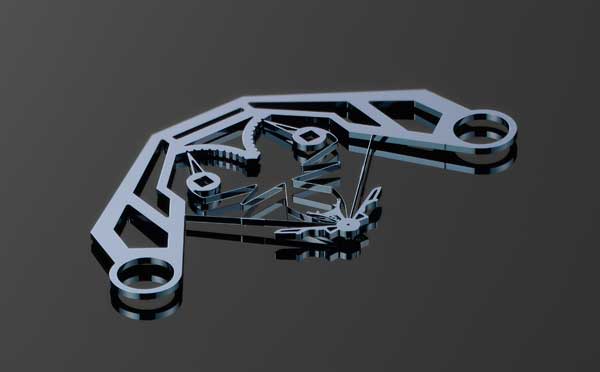

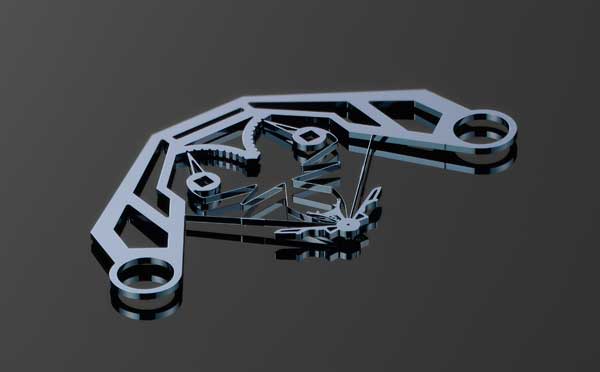

1. Dual Constant Escapement

The Dual Constant Escapement is an evolution of the design of the Ulysse nardin watch 356-66 price Replica Dual Direct escapement. Based around a highly complicated component made out of one piece of silicon, the Dual Constant Escapement ensures constant force of the impulses on the balance wheel because they are independent of the tension of the mainspring. Two flexible blades incorporated into the escapement bridge (see image below) are alternately pre-tensioned with each vibration of the balance wheel. Each blade then releases its energy rapidly on the next vibration (the two vibrations making up one oscillation), governed by one of the two escape wheels.

2. Direct silicon bonding

DRIE (Deep Reactive Ion Etching) or photolithography is the name of the process used to produce the escapement from silicon. Because plasma is used in this process, the resulting silicon has a hydrophobic surface. The advantage of hydrophobic silicon wafers in direct bonding is that at high temperatures (1000 to 2000 degrees Celsius in this case), a genuine direct silicon-silicon bond is formed, meaning that the two components become one, with the bond having the same cohesive strength as bulk silicon. This is the first time direct silicon bonding has been used in watchmaking.

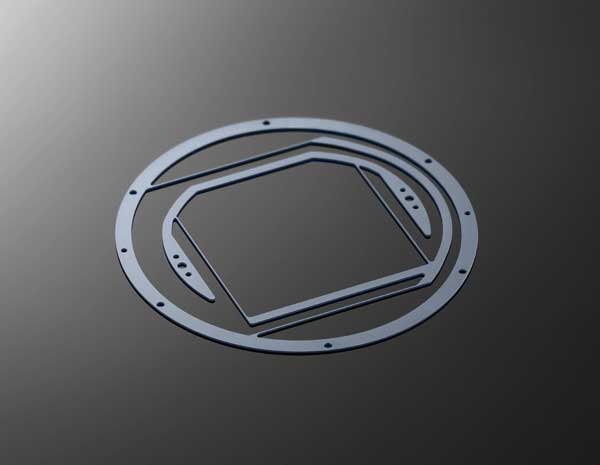

3. Silicon balance wheel with gold mass elements and stabilizing micro paddles

The key to good balance wheel design (and therefore optimum chronometric precision) is to have the lightest possible mass at the central axis of rotation but nevertheless have a high moment of inertia. This is usually achieved by adding weighs around the circumference of the balance wheel to add mass. Ulysse Nardin takes this to the next level with a design that builds the wheel up from silicon wafers to form a component that weighs just seven milligrams. Four mass elements, in the shape of the Ulysse Nardin logo and anchor, are then added at the four cardinal points on the wheel, each with a gold element that can be adjusted to regulate the moment of inertia.

![]()

Lastly, we come to what I feel is that the star of this show, the Ulysse nardin watches 2015 Replica Marine Torpilleur Military watch. Unlike the previous two models, this watch does not feature a Grand Feu enamel dial. What distinguishes the Ulysse Nardin Marine Torpilleur Military from its compatriots is that this could be regarded as a “true” marine chronometer, in the sense that high precision, strong legibility, and an over-engineered movement take precedence above all other concerns for this particular timepiece.The Ulysse Nardin Marine Torpilleur Military is quite much like some previous Torpilleur model we covered recently, sharing the same movement and even the exact same title, with the inclusion of “Military” being the key differentiation. This Army variant is 2mm larger than the last version, opts for Arabic rather than Roman numerals, also lacks both the date and power reserve complications. The small seconds monitor at 6 o’clock offers a red serial number ranging from 1 to 300, as the Ulysse Nardin Marine Torpilleur Military is a 300-piece limited edition. Just underneath the serial number are the initials C.W. which stands for “Chronometer Watch. “The Ulysse Nardin Marine Torpilleur Military is powered with the UN-118 in-house movement, which features an escapement in DIAMonSIL, a combination of silicon with man-made diamond. This exceptionally hard but light material is the result of a collaboration between Ulysse Nardin and Sigatec in Sion, Switzerland, who specialize in the production of micro-mechanical silicon components. This DIAMonSIL escapement works with essentially no friction, requires no lubrication, and ought to provide lengthy service periods and greater precision over time. Even the silicium oscillator of the UN-118 motion can also be produced in-house by Ulysse Nardin and comes with a patented inertial balance wheel with screw adjustment.

4. “Grinder”

Inspired by the world of yacht racing, in which Ulysse Nardin is involved as a partner of Artemis Racing, the “grinder” is an entirely new design for the self-winding mechanism of the Innovision 2. Like the grinders found on racing yachts, it allows rotational energy (provided by muscle power on a yacht and the winding rotor in a mechanical watch) to be used efficiently, by means of a reduction gear, to wind the mainspring barrel. The innovation of the “Grinder” is a flexible ring that acts as an interface between the oscillating mass and the winding wheel. Each rotation of the oscillating mass causes one or two of the four ratchets on the intermediate ring to turn the winding wheel directly, with a minimum of play.

5. Sapphire-coated silicon bridge

Ulysse Nardin has long been a pioneer in the treatment of silicon components. Having “grown” polycrystalline diamond on its silicon components in the past, the brand has now developed, in conjunction with Sigatech and the EPFL in Lausanne, a new means of coating silicon components with a one-micron film of sapphire. The advantages are harder surfaces and greater mechanical stability.

6. 24-carat gold wheels

Gear wheels are usually made of brass, but in the Innovision 2 they are made of 24-carat “hard” gold. This is done using the photolithographic LIGA process, which creates a more stable structure and reduces friction on the steel pinions compared with brass.

7. Glass bridge with integrated shock protection

Unlike any other shock-absorbing system on the market, the mechanism used in the Innovision 2 is made out of a single piece of glass, with an integrated coil spring. The main advantage is reduced friction, since the five separate elements used in conventional shock absorbers like the Incabloc add extra sources of friction; the monobloc construction of the glass bridge removes them.

8. SuperLuminova filled channels in the glass bridge

This is more an innovation in the manufacturing process than a genuine innovation in the product. The manufacturers of the glass bridge were able incorporate tiny channels within the glass, which have been filled with luminescent material.

9. New time display

It’s one of those things that appear so obvious, yet nobody had thought of it until now. Although the day is made up of 24 hours, most watch dials are configured to display just twelve. The Innovision 2 dispenses with this minor annoyance by using a disc on to which two separate scales are printed (1-11 and 13-23). At midday and midnight, the ring shifts the display accordingly over a 15-minute period.

10. Three-dimensional glass minute hand

To complement the innovative glass bridge, Ulysse nardin watches limited edition price Replica uses laser-cut glass for the large minute hand that covers the entire gear train of the movement.

As the innovations in the first Innovision, as well as the developments throughout the course of the Freak’s history have shown, you can expect to see many of the above innovations find their way into Ulysee Nardin’s production models over the coming years.